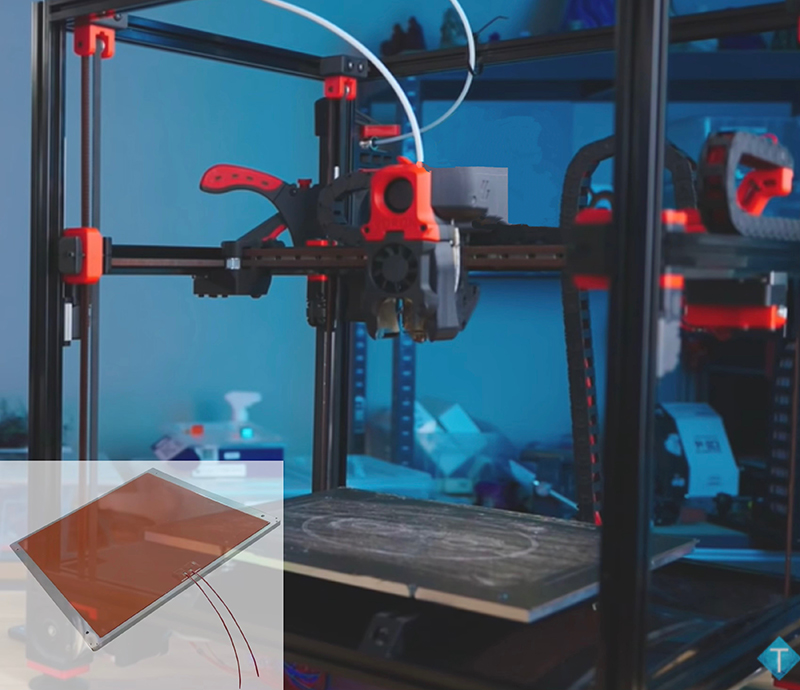

Silicone heaters are a key component in 3D printer heated beds, ensuring the first layer of prints adheres properly and preventing warping. These heaters heat up quickly and distribute heat evenly across the bed, making them ideal for materials like ABS and PETG. Paired with glass-encapsulated NTC thermistors, they provide precise temperature control, which is critical for consistent, high-quality prints.

What Makes Silicone Heaters Special?

Achieving perfect first-layer adhesion is critical for successful 3D printing. Silicone heaters deliver this precision through advanced materials and engineering that outperform standard heating solutions. Here's what sets them apart:

1. Fast & Even Heating: Made from nickel-chromium alloy heating wires and fiberglass-reinforced silicone rubber, they heat up quickly and spread warmth evenly across the bed.

2. Customizable: Available in sizes from 15mm x 15mm to 1.2m x 2m, with thickness options from 0.8mm to 4.5mm. Power and voltage can be tailored to meet specific heating requirements.

3. Durable & Safe: With a maximum operating temperature of 250°C and insulation resistant to 300°C, they are built for long-term use.

4. Easy Installation: Backed with pressure-sensitive adhesive for secure attachment to the heated bed.

How Silicone Heaters Solve Real-World Problems?

A 3D printer manufacturer faced challenges with warped prints and poor first-layer adhesion, particularly when using ABS and PETG materials. Warping and uneven heating were causing frequent print failures, leading to wasted time and materials.

To address this, our team developed custom silicone heaters tailored to their heated bed size and power requirements. The heaters were designed with 3M adhesive backing, allowing the client to easily assemble and secure them to the heated bed without additional tools or complications. Paired with glass-encapsulated NTC thermistors, the heaters provided precise temperature measurement and control, ensuring consistent heat distribution.

After installation, the client reported a 30% reduction in print failures and a 20% improvement in first-layer adhesion. The dual-temperature control system (thermistor + control board) maintained optimal printing conditions, even during long prints. This solution not only improved print quality but also streamlined the assembly process, saving time and enhancing the overall reliability of their 3D printers.

Why Silicone Heaters Are Essential for 3D Printing?

Warped prints and poor adhesion ruin 3D printing results. Silicone heaters solve these problems with rapid, even heating that prevents material shrinkage and ensures perfect first-layer bonding. Their durable construction withstands continuous 250°C operation while maintaining precise temperature control.

For both hobbyists and manufacturers, these heaters deliver reliable performance that directly improves print success rates. The easy-adhesive installation simplifies upgrades to existing printers. When print quality matters, a properly heated bed makes all the difference - and silicone heaters deliver that foundation consistently.

Die 3d-druckentwicklung durch verlässliche heiz-lösungen erhöhen

Heizung für silikonEin essentieller bestandteil des 3d-druckens, um sicherzustellen, dass die ersten schichten richtig kleben und die warzen nicht aufrollen. Diese fasern bestehen aus ni - und chromchrom und den faser, die das silikon erhitzen und schnell erhitzen und gleichmäßig hitze auf dem bett verteilen.

Die verbindung mit wärmesensoren (NTC) und ostfiürem widerstand (NTC) bietet exakte temperaturregelung, die für einen verbesserten ausdruck unerlässlich ist. (und nicht nur für fachleute wie auch für industriezwecke liefern sie die gewünschte präzision und zuverlässigkeit für einen erfolgreichen 3d-druck.)

Wir bieten alle arten Von effizienten heizungen und heizgeräten. Lager - und typ-heizgeräte, lager - und pet-heizgeräte, lumpenlampen - und pc-heizgeräte, pc-geräte, - rolex - und stylen-heizgeräte.